The Fred R. & Olga K. Pace Materials Lab supports our mission to provide environments in which to explore, model, fabricate and test design ideas.

In total, the labs comprise a 9,000 square-foot facility, providing a professional quality environment with equipment accommodating a wide variety of materials including metals, woods, concrete, ceramics, glass and more.

The labs are governed by the policies below in order to ensure your safety and appropriate use of the facility. Users of the labs are responsible for understanding and complying with these policies. Access will be provided only upon successful completion of the following:

- A one-time Brightspace online training (instructions below)

- A one-time in-person training the labs

- An annual safety procedure online test and signed formal contract asserting your agreement to abide by lab rules and regulations (instructions here)

Step 1: Log into Brightspace (opens in a new tab) https://d2l.arizona.edu/d2l/home

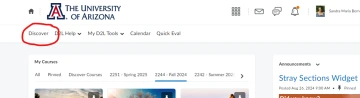

Step 2: Select the Discover link in the Navbar.

Step 3: Select Browse All Content.

Step 4: Type "CAPLA Materials Lab: Safety Training & Contract" in the search box and select the Search icon.

Step 5: Select the name of the course in the results list. This will take you to the course enrollment page.

Step 6: Select the Enroll in Course button to self-enroll for the course.

Step 7: When the enrollment is complete, select the Open Course button to go directly to the course.

Step 8: The next time you want to open this course, select the Discover Courses tab in the My Courses widget on your D2L Homepage.

ONCE IN THE CAPLA Materials Lab: Safety Training & Contract follow the instructions in the main page.

IMPORTANT

The Brightspace portion (Part1) is only required one time during your degree.

We will perform random D2L checks to confirm that you first passed Part 1(the online portion on this site). If we find you noncompliant, we may suspend your access until you are compliant.

During the fall and spring semesters, the labs are open to all CAPLA students and faculty who have passed the safety requirements. Generally, hours are from 8 a.m. - 7 p.m., Monday through Friday, and noon - 5 p.m. on the weekends. Labs are closed for winter/summer breaks unless otherwise noted. Please contact the Material Labs Manager for additional information.

Policies and Procedures